SAP has released the 2023 release (Feature Pack Stack FPS0) of SAP S/4HANA Cloud, private edi 2024-1-11 02:44:26 Author: blogs.sap.com(查看原文) 阅读量:48 收藏

SAP has released the 2023 release (Feature Pack Stack FPS0) of SAP S/4HANA Cloud, private edition on 11th October 2023.

This blog post provides an overview of innovations for Supply Chain Management.

For a focussed start, check out the next video from Markus Oertelt highlighting the following innovations:

- Advanced Shipping and Receiving for Decentralized EWM and TM

- Warehouse Management – Advanced Shipping and Receiving Cockpit

- Transportation Management – Calculation of Greenhouse Gas Emissions

- Inventory Management – Composite Barcode Scanning

Video 1: Highlights for Supply Chain Management in the 2023 release

Table of content (for quick access, just click on one of the business area links):

-

Advanced Intercompany Processes

-

Advanced Available-to-Promise (aATP)

-

Handling Unit Management

-

Process Flow Transparency

-

Inventory Management

-

Extended Warehouse Management

-

Transportation Management

-

Kanban

-

Delivery

-

Extended Service Parts Planning

First, we launched the Advanced Intercompany Processes in SAP S/4HANA Cloud, public edition with the 2208.3 release. Since this time, the blog post

has attracted particularly great interest.

Advanced intercompany business processes include Advanced Intercompany Sales and Advanced Intercompany Stock Transfer.

With the 2022 release, we made Advanced Intercompany Processes also available in SAP S/4HANA and SAP S/4HANA Cloud, private edition, see the blog post

What’s new for Adv. ICo with the 2023 release?

Configure Posting Date for Advanced Intercompany Invoices

In Customizing for Materials Management under Advanced Intercompany Business Processes the new Customizing activity Configure Posting Date for Advanced Intercompany Invoices is available: You can specify for each individual invoicing party which date is to be used for the posting date of the intercompany supplier invoice:

- If you leave the Invoicing Party field blank but specify a value for the posting date, this posting date is used for all invoicing parties that are not explicitly specified.

- If neither a specific entry nor a default entry exists for an invoicing party, the billing date from the referenced billing document is taken as the standard behavior.

Figure 1: New configuration step ‘Configure Posting Date for Advanced Intercompany Invoices’

Deactivation of Advanced Intercompany Sales

You can deactivate the Advanced Intercompany Sales process (scope item 5D2), for example, if you want to switch to the classic intercompany sales process.

For this purpose, you can use the business add-in (BAdI) BADI_SDSLS_VCM_PROC_DEACTIVATE (Deactivation of Advanced Intercompany Sales) to define that an intercompany sales order item should not be processed as an advanced intercompany sales order item.

If you deactivate the Advanced Intercompany Sales process, you can switch to the classic intercompany sales process.

Sujeet Acharya summarizes the aATP innovations in his blog post

In my past blog post

you will find a list of further blog posts about

- Supply Creation-Based Confirmation (SBC),

- Supply Protection

- Product Allocation

- Backorder Processing

In addition, I want to draw your attention to two new blog posts:

Customer Defined Packing and Picking

With the new app Manage Handling Units in Production – Scheduling Agreement, the user with the role of Production Supervisor – Repetitive Manufacturing can create planned handling units for sales scheduling agreement items in the repetitive manufacturing context.

Figure 2: Fiori app ‘Manage Handling Units in Production – Scheduling Agreement’ (F6445)

The app is one step in an end-to-end process, called Customer defined Packing and Picking, including new functionality in EWM.

It is the successor of the old transaction MFPP (Create Planned Handling Units) but only for scheduling agreements.

Handling Unit Situation

For some products shipped with handling units it is critical, that during the delivery certain basic conditions are met, for example, regarding the temperature, the humidity, or vibrations. To monitor these handling units, you can attach sensors to the handling unit before it leaves your warehouse to make sure that you get informed when defined thresholds are exceeded. The sensors send their data to a third party Internet of Things (IoT) system, which then creates a situation using the Handling Unit API to inform the shipping specialist. The person receives this notification, which leads to the relevant entry in the My Situations app. In the app, the shipping specialist can see, for example, which handling unit is affected and what the sensor detected. You can adapt the displayed texts to your own business purposes.

Let’s take a closer look how the Handling Unit Situation scenario is technically realized:

ODATA API: Handling Unit

You can now use the MoveHandlingUnits operation of the ODATA API Handling Unit to perform good movement postings for handling units for additional business scenarios. The next figure shows the capabilities of the API for movement from a non-HU-managed storage location:

Figure 3: ODATA API Handling Unit – Movement from non-HU-managed storage location

With the new CreateSituation operation, you can now create situations for handling units managed in storage locations in Logistics (LO) as well as in Warehouse Management (WM). This new operation can be used by third party Internet of Things (IoT) systems, which collect information from connected sensors attached to handling units.

Figure 4: Handling Unit Situation – Architecture

Situation Template: Handling Unit Situation

Use the new standard template for Handling Unit Situation if you want your users to be informed instantly when the measurement of a sensor attached to a handling unit exceeds its defined threshold. The user gets a notification, which leads to the relevant entry in the My Situations app.

Figure 5: ‘Manage Situation Types’ app – Use new situation template ‘Handling Unit Situation’ instead of deprecated situation template ‘Handling Unit IOT’

The next figure shows the details of the new situation template in the Manage Situation Types app.

Figure 6: ‘Manage Situation Types’ app – Detail page of new template ‘Handling Unit Situation’

For this new situation template, the information concerning critical situations of the handling unit, for example, the temperature threshold is exceeded, must be sent to a third party Internet of Things (IoT) system, which then creates the situation using the Handling Unit API. For more information, see CreateSituation.

The next figure shows how the user will be informed about the situation in the app Monitor Handling Units. I recorded the screenshot from a test scenario in a SAP S/4HANA Cloud, public edition system. But consider that the app Monitor Handling Units is only available in SAP S/4HANA Cloud, public edition.

As mentioned above, in SAP S/4HANA, you can see the situation in the app My Situations.

Figure 7: ‘Monitor Handling Units’ app – Situation notification informs the user that the threshold of 40 CEL was exceed and the current temperature of the handling unit is 77 CEL.

For further information, see Handling Unit Situation.

Are you using a Web shop app that is connected to an SAP S/4HANA backend system? And do you want to efficiently monitor the logistics processes of your sales orders within SAP S/4HANA?

The solution for you is Process Flow Transparency.

For a short introduction in Process Flow Transparency read my past blog post

Check out the brand new blog post

from Simon Liebel in which he demonstrates a practical use case scenario to show how Process Flow Transparency can benefit your business.

Composite Barcode Scanning

Barcode scanning is widely used for various purposes due to its efficiency and accuracy in capturing and processing information. Barcodes provide a unique identifier for each product. Scanning barcodes eliminates the need for manual data entry, which can be time-consuming and prone to errors. Barcodes facilitate efficient inventory management by enabling real-time tracking of products entering and leaving a warehouse or store. Scanning barcodes during receiving, picking, and shipping operations helps maintain accurate stock levels, reduce stockouts, and optimize reordering.

In recent releases, we have already enabled barcode scanning in many Inventory Management apps (see my blog posts for the releases 2021, and 2022).

The next figure describes the difference between scanning of simple or composite barcodes in SAP S/4HANA Inventory Management:

Figure 8: Barcode scanning in SAP S/4HANA Inventory Management

Now, the possibility to handle composite barcodes has been added to the barcode scanning function in the apps:

- Post Goods Receipt for Purchasing Document

- Post Goods Receipt for Production Order

- Post Goods Receipt for Process Order

- Post Goods Receipt for Inbound Delivery

- Post Subsequent Adjustment

- Stock – Single Material

- Manage Stock

- Transfer Stock – In-Plant

Such barcodes are based on the international GS1 standard (see GS1 General Specifications Standard) that allows defining multiple information in one barcode. The next figure shows a composite barcode that e.g. contains GTIN, Packaging Date, and Batch information.

Figure 9: Composite Barcode

Please note that industry is moving toward two-dimensional (2D) barcodes. Check out the GS1 announcement Get Ready for Sunrise 2027. All linear barcodes will be replaced with GS1 QR codes by 2027. SAP S/4HANA Inventory Management is ready for the change.

Therefore, a new central configuration setting has also been created for this purpose. For more information, see Barcode Scanning in Inventory Management.

The next figure summarizes the customizing steps for barcode scanning in Inventory Management.

Figure 10: Customizing for barcode scanning in Inventory Management

Check out the next demo video in which Stefanie Bierbach, Product Owner for Inventory Management shows the composite barcode scanning in the Manage Stock and Transfer Stock – In Plant apps.

Video 2: ‘Manage Stock’ app – Composite Barcode scanning + Mass processing via ‘Item List’

In addition, the demo video above shows the new Add To List action and Item List section that is described in the next chapter.

Manage Stock – Mass posting with Item List for stock mass posting

The new Add To List action and Item List section enables mass processing for the apps:

- Manage Stock

- Transfer Stock – In-Plant

You can post more than one material at the same time if you first temporarily save the selected materials in an item list (Add To List action). From this item list, you can later select the materials to be posted at once.

Figure 11: ‘Manage Stock’ app – ‘Add to List’ action for mass posting on ‘Item List’ section

Manage Stock

Enhancements to Manage Stock app

You can now use the goods issue for cost center (201 postings) and special stock type K (supplier consignment) in the Manage Stock app.

If you use serial numbers, you now have the flexibility to create new serial numbers for a storage location while transferring or scrapping materials even if you have a stock check warning or no stock check selected in your serial number profile.

Figure 12: ‘Manage Stock’ app enhancements – use for movement type 201, special stock type K, create new serial number while transferring or scrapping materials

Usability Improvements

The Stock – Single Material App is now enhanced to provide filter options for fields like plant, batch. This helps customer to find and load preferred plants.

Figure 13: ‘Stock – Single Material’ app – new filter options for fields like plant and batch

Further, you can also now have additional settings to exclude batches with deletion flag, exclude batches with zero stock in the Transfer Stock – Cross Plant app.

Figure 14: ‘Transfer Stock – Cross Plant’ app – new view settings to exclude empty batches and batches with deletion flag

Analyze Stock in Date Range and Schedule Export for Inventory Analytics

With the 2022 release, we launched the SAP Fiori app Analyze Stock in Date Range that enables you to analyze and monitor goods movement postings for one or more materials in a defined date range (see my 2022 blog post ).

In the app, you can now do the following:

The job scheduling function has been enhanced to start an export report to Microsoft Excel with the

inventory analysis results. The new button Schedule Export has been introduced for direct access. Alternatively, you can open the app Schedule Export of Inventory Analytics from the Fiori launchpad as show in the figure below. With this app, you can schedule a background job to export material stock and posting data for a defined time period. Since the retrieval of large queries can be time-consuming, SAP recommends that you move such queries to resource-uncritical phases of the day.

Figure 15: Open ‘Analyze Stock in Date Range’ app (F6185) and ‘Schedule Export of Inventory Analytics’ app (F7493) from Fiori launchpad or use button ‘Schedule Export’ for direct job scheduling

The new button Schedule Export for direct access to job scheduling is available in both the main page and the detail page of the Analyze Stock in Date Range app.

Figure 16: ‘Analyze Stock in Date Range’ app – Detail page with button ‘Schedule Export’

Check out the SAP Help Portal in case of any questions about the Analyze Stock in Date Range app:

- Analyze Stock in Date Range | SAP Help Portal

- Details for Calculating and Displaying Values | SAP Help Portal

Physical Inventory

Create Physical Inventory Documents

The usability of the Create Physical Inventory Documents app has been improved:

- A new filter allows you to select either materials with or without movement. Now, you can also use this app to create physical inventory documents for materials for which no material documents exist.

- You can now schedule a background job that processes the creation of physical inventory documents. In addition, you can combine this creation with a print option using the same background job.

Figure 17: Schedule Physical Inventory Document Creation

Manage Physical Inventory Documents – Post all items at once

The posting function in the Manage Physical Inventory Documents app has been enhanced. You can now make mass postings more conveniently and more quickly. Instead of selecting individual items of a physical inventory document, you can now select and post all items of a physical inventory document at once. Before posting for a complete physical inventory document, you can specify in a dialog the reason for each item difference type (increase/decrease). The possible reasons are displayed in the value help.

Figure 18: ‘Manage Physical Inventory Documents’ app – post all items of a physical inventory document at once

Label Printing in Goods Receipts

You can now you can print multiple goods receipt slips and/or labels when posting a goods receipt in the following apps:

- Post Goods Receipt for Purchasing Document

- Post Goods Receipt for Production Order

- Post Goods Receipt for Inbound Delivery

- Post Goods Receipt for Process Order

- Post Goods Receipt without Reference

In the newly added Number of Labels field, you can manually enter the number of labels to print or let the system calculate the number of printed labels for you. In both cases, you must first maintain the Label type and Lab. Form fields in the material master record under the plant data view.

Figure 19: ‘Post Goods Receipt for Purchasing Document’ app – new field ‘Number of GR Slips’ on GR item object page

Consignment Stock Reporting

With the Consignment Stock Reporting apps, you can keep an overview of goods movements going in and out of your consignment stock and set up an automated email notification to suppliers about the current state of their stock. This process helps expedite stock replenishment and provides stock transparency.

Consignment Stock Reporting includes 3 apps:

For detailed information how to set up the scenario, check out the SAP Help.

The following figures show the three new apps:

Figure 20: ‘Manage Stock Reporting Procedures’ app

Figure 21: ‘Manage Stock Reporting Subscription’ app – Object Page

Figure 22: ‘Stock Reporting Overview’ app

Figure 23: ‘Stock Reporting Overview’ app – Object Page

Florian Kuchta gives an comprehensive overview of innovations and new features in SAP Extended Warehouse Management. I encourage you to read his blog posts:

- SAP® Extended Warehouse Management in SAP S/4HANA 2023 – What’s New

- SAP Extended Warehouse Management in SAP S/4HANA 2022 FPS01 – What’s New

Eric Osterroth gives an comprehensive overview of innovations and new features in SAP Transportation Management. I encourage you to read his blog posts:

- Highlights of Transportation Management in SAP S/4HANA 2023 Release and SAP S/4HANA Cloud, private edition

- SAP Transportation Management in SAP S/4HANA 2022 – FPS01 – What’s new?

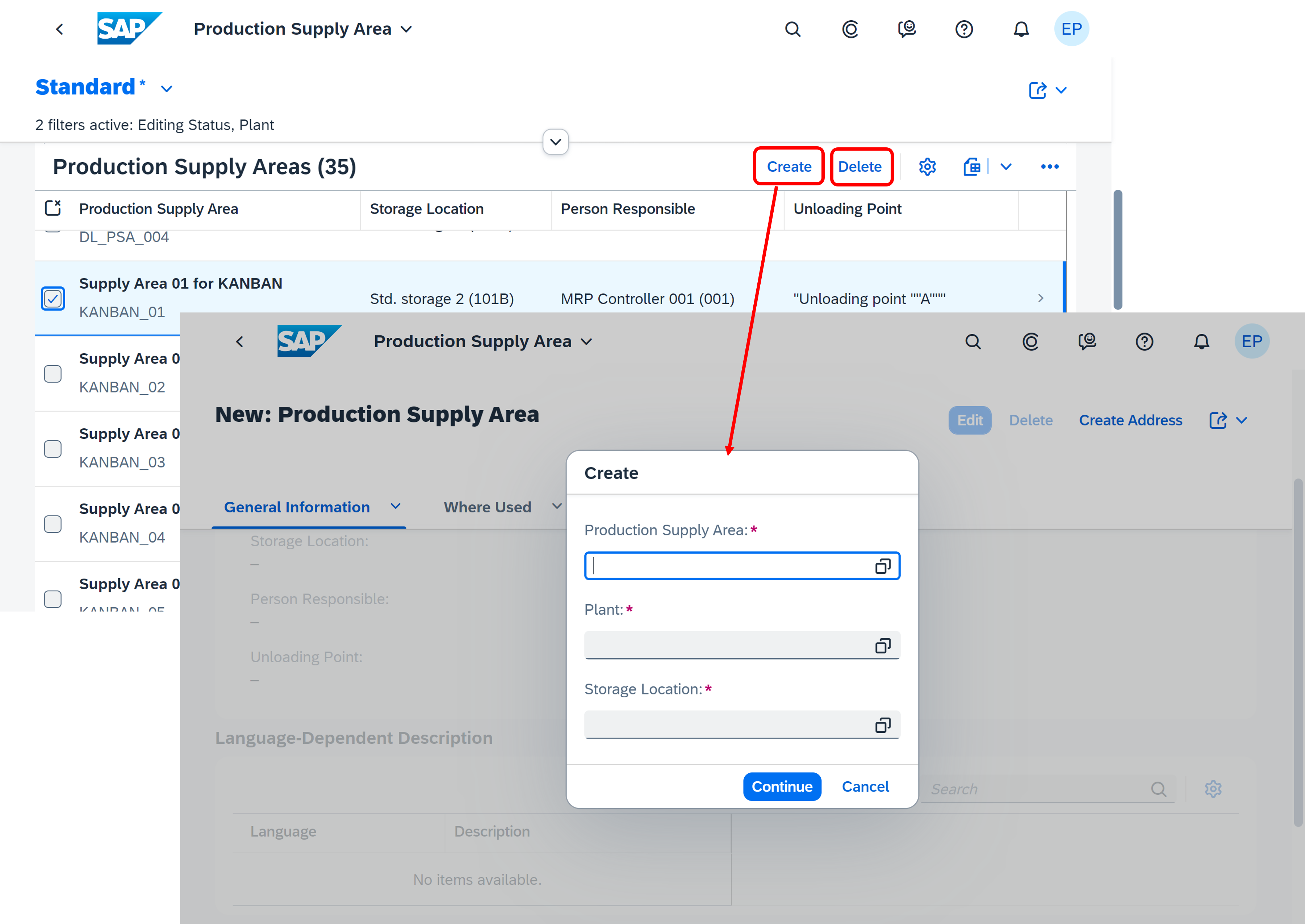

Kanban – Manage Production Supply Areas

The new SAP Fiori app Manage Production Supply Areas (F6935) helps you to manage your production supply areas and enables you to create, edit, and delete production supply areas. You can personalize the displayed list of production supply areas according to your use cases. You can navigate to further details including in which contexts production supply areas are being used.

Figure 24: SAP Fiori app ‘Manage Production Supply Areas’ – Create, edit, and delete functionality

Kanban Container Status

Define Kanban Container Status Texts

With this feature you can define container status texts in different languages. The maximum length for the container status text has increased to 12 characters. You can overwrite the predefined container status texts, to improve usability and understanding of Kanban processes in your environment.

Figure 25: Configuration of own status text

Define Kanban Container Status Sequences

With this feature you can define kanban container status sequences, and permissions or restrictions for container status changes. In the control cycle you can select one of your status sequences in preference to a predefined status sequence.

Figure 26: Definition of own status sequence

Kanban Stock Transfer with Warehouse Requests for Embedded EWM

A new kanban replenishment strategy is available for embedded EWM stock transfer using warehouse requests.

So two stock transfer possibilities are now available on a decentral EWM system:

- Stock transfer with warehouse task

- Stock transfer with warehouse request (new)

Figure 27: Stock transfer with warehouse request on decentral EWM – System architecture

Figure 28: Stock transfer with warehouse request on decentral EWM

You can choose the new control type Stock Transfer with Warehouse Request in the configuration activity Kanban -> Replenishment Strategies -> Define Stock Transfer Strategies.

For further information, see Replenishment Strategies for Stock Transfer.

Enable Inbound Delivery Processing for Serialized Subcontracting Components

You can now enter and display serial numbers for subcontracting components in the Change Inbound Delivery (VL32N) app.

In addition, the following services are extended and supporting now serial numbers for subcontracting components in inbound deliveries:

- SOAP API: Inbound Delivery – Create (B2B) (DELIVERYREQUEST_IN)

- Odata API: Inbound Delivery (A2X) (API_INBOUND_DELIVERY_SRV_0002)

Figure 29: Odata API Inbound Delivery (A2X) – serial numbers are now supported for subcontracting components

Prerequisite: In order to use serial numbers for subcontracting components in inbound deliveries, the component must have a serial number profile assigned at the time of the inbound delivery.

Further integration enhancements to Advanced Variant Configuration

Now you can navigate from the Delivery Fact Sheet to the configuration values in the AVC UI. In addition, you can print the configuration values of the delivery items on Delivery Notes.

Figure 30: Navigation from Delivery Fact Sheet to the configuration values in the AVC UI

Forecasting

Multiple external time series in Forecasting

Let us delve into an example showing the relationship between Demand History and Temperature.

Figure 31: Example showing the relationship between Demand History and Temperature

You can now

- Maintain one or multiple external time series that capture the behavior of an external factor (e.g. temperature, gross domestic product, installed base of engines etc.) over time.

- Use external time series in forecasting (currently limited to forecast models of Gradient Boosting and ARIMAX) as an independent variable.

- View external time series alongside location / product key figures within the Interactive Forecast UI.

and

- Planning levels supported for external time series include Product and Location, Product only, Location only, Region, or Product Group.

The major benefit of using external time series is the ability that forecast models can account for the potential impact of external factors on your forecasts. This results in a higher forecast accuracy, leading to more informed decision-making and strategic planning.

The next 3 figures show the customizing steps to Maintain Time Series Profile and Assign key figures to External Time Series Profile:

Figure 32: Step 1 – Transaction SPRO “Define Profile for External Time Series”

Figure 33: Step 2 – Transaction SPRO “Define Forecast Service Profile” – Link TS ID in Forecast Service Profile

Figure 34: Step 3 – Transaction /SAPAPO/SPPFCSTPRF – Link TS ID in Forecast Profile

Forecast with ARIMAX Model

Make use of the intelligent ARIMAX forecast model to enhance planning quality. You can now

- Leverage the autoregressive integrated moving average algorithm with additional external data (ARIMAX) in eSPP

- Forecast the need for spare parts in upcoming periods based on past values and include additional key figures

- Use automatic model selection to determine if ARIMA, ARIMAX or any other Forecast model is a best fit

Figure 35: Forecast with ARIMAX Model

Gradient boosting of decision trees in Forecasting

Now we come to artificial intelligence! Use gradient boosting of decision trees forecast with multiple external time series to enhance planning quality. This feature offers the following capabilities:

- The ability to upload an external time series and the provision of the gradient boosting of decision trees model allow you to use a machine-learning forecast that incorporates external data to generate a better forecast.

- This scope item will provide an improvement of the user experience and allow to utilize multiple external time series in eSPP (Extended Service parts) forecasting.

- Along with historical data and forecast figures, users can display multiple external time series in the interactive forecasting UI.

Figure 35: Gradient boosting of decision trees in Forecasting

Distribution Requirements Planning (DRP) – Repair or Buy

With the Repair or Buy functionality you can plan the repair of already used, broken and returned (unserviceable) parts. Using this feature, eSPP Distribution Requirements Planning (DRP) runs result in planned refurbishment orders in case of an in-house repair or in purchase requisitions in case subcontractors are involved. Parts of the required demand may also be replenished via external procurement instead of repair, as usual in eSPP. In many cases the repair of parts is more cost-efficient than the procurement of completely new parts.

Figure 36: Use repair-or-buy functionality to gain planning accuracy by covering demand using repairable products

In addition, eSPP offers many new features also in the area of Capture Demand, Inventory Planning, and Cross-functional topics that are described in the What’s New document. For more information watch the recording of the eSPP session during our last product expert training (see link in the next chapter).

Thanks for reading this blog post. Stay tuned!

If you are also interested in other Lines of Business and Industries for this new SAP S/4HANA Cloud, private edition 2023 release, I would like to draw your attention to the blog posts

- SAP S/4HANA Cloud, private edition | 2023 Release from Christian Vogler

- 2023 Release Highlights in Seconds: SAP S/4HANA & SAP S/4HANA Cloud, private edition | SAP Blogs from Noboru OTA.

If you want to see the entire PDF presentation of all innovations, see here.

If you want to learn more about SAP S/4HANA Cloud, private edition, join our Partner Community. This group focuses on providing enhanced learnings and periodic updates with respect to the SAP S/4HANA Cloud, private edition product. Our goal is to facilitate collaboration with your peers and SAP subject matter experts.

For general roadmap information please check the SAP S/4HANA Roadmap.

If want to learn more about the described innovations watch the recording of the last Product Expert Training that you will find on our landing page (see Sessions in Week 2 -> Plan to Fulfill track).

Further Information:

- SAP S/4HANA Cloud for Manufacturing & Supply Chain – The Link Collection

- SAP S/4HANA Cloud, private edition release info: com/s4hana

- SAP S/4HANA Cloud, private edition, and SAP S/4HANA Community here

- SAP S/4HANA PSCC Digital Enablement Wheel here

- Inside SAP S/4HANA Podcast here

- Best practices for SAP S/4HANA Cloud, private edition here

- Help Portal Product Page here

- Feature Scope Description here

- What’s New here

Follow us via @SAP and #S4HANA, or myself via @GerhardWelker and LinkedIn

如有侵权请联系:admin#unsafe.sh