Here is my another blog, an overview of exception handling.

With an example to demonstrate exception code – BIDP (Partial pick denial)

Exception handling in EWM is to fill the gap between physical and system data, any inconsistencies caused during Putaway/Picking/Physical inventory, or any other internal process can be corrected using exception codes.

It enables the warehouse operator to correct the operation in such inconsistent cases by entering the Exception Code

This blog describes definition of exception code, profiles, business context and other detail configurations with step-by-step screen shots of standard SAP EWM config. It shows complete knowledge of what exception code is and how to use it with example (outbound – picking sample example is explained in this document)

Definition of exception handling/code comes under cross-process settings –

Maintaining Business context: Business context in which special exception codes can be made available, Example Confirm warehouse task, and count physical inventory.

Next step is to assign operation to this business context, that is execution step.

This is to tell system that in which framework/platform user is using exception code.

Ex: Desktop, RF Gun

This combination of business context and execution step is assigned to internal process codes. Internal process code is the Parameter delivered by SAP that controls internal processes upon execution of an exception code.

Assign business context and execution step to Status management (STM action) –

Example: The exception code Storage bin is not accessible should be coupled with the status change that that the bin is locked for removals from stock. All planning routines would take the new status into account.

— — — — — — — — — —

Define exception code: Allows you to create or use existing 4-character code under warehouse level

SAP has provided option to block any given exception code, if that seem to be mis used by any resource or if it is causing unnecessary problems.

So, SAP has also provided two standard profiles, to prevent unqualified personnel from using exception codes with extensive follow-up actions. By linking the user ID with the exception profile, you can ensure that only this group of persons can execute special exception codes.

For the Exception code, we add business context.

Where can we use and who can use the code (Excp. Code profile) – as shown below.

Workflow can be set for follow-on action, it could be supervisor approval, e-mail alert etc.,

* * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * *

Example to demonstrate exception code – BIDP (Partial pick denial)

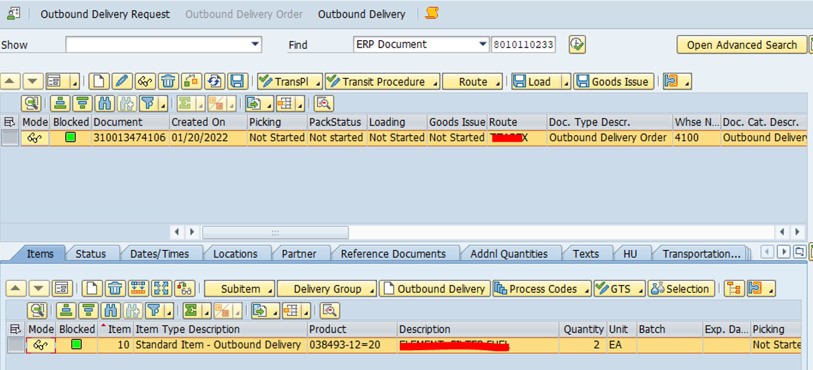

Created a standard sales order and outbound delivery

While processing picking task, we use this exception code (BIDP)

That means in given bin – partial product quantity is damaged, so picker uses this code and pick only partial quantity and move to next bin to complete warehouse task.

Lets Confirm this in /SCWM/RFUI

Using status management, we can block the bin for stock removal…

When user enter BIDP, system allows to pick partial quantity and confirm picking. For remaining quantity system propose new bin as shown above.

Hope this helps, your feedback is much appreciated.

如有侵权请联系:admin#unsafe.sh