2023-10-27 15:19:18 Author: blogs.sap.com(查看原文) 阅读量:5 收藏

SAP Integrated Business Planning for Supply Chain 2311 comes with great enhancements, and so the SAP Best Practices for IBP does. Let’s take a look at the main topics:

Enhancements and changes for Sample Model SAPIBP1

As you might know, we update and enhance the sample planning area SAPIBP1 in every release. This is important because we have to ensure that new functionalities in the different application areas work together with SAPIBP1.

- New key figures for CO2 emissions rollup operator

In release 2308 the network aggregation operator was introduced. This operator can calculate costs or carbon emissions at every location throughout the supply network in every period of the planning horizon. In 2311 we enhanced SAPIBP1 with a set of key figures and planning levels that allow you to calculate several key figures for aggregated values or values at node. - New key figures for service level prediction in inventory

To support the new service level prediction operator in inventory optimization, three new key figures have been created. - The next one is a pretty important change you should be aware of: The change of multiple sample attributes to uppercase values only. The reason is that their origin in SAP ERP or SAP S/4HANA is stored in uppercase value. It’s important that you only implement this change in your planning area if you are sure that your current attribute data is stored with uppercase values.

- A new attribute and a new key figure for fixed capacity consumption in production. This enhancement is needed because the optimizer algorithm has been enabled to consider fixed capacity consumption in production.

For all changes and more details, please check the detailed SAPIBP1 documentation in the IBP help – what’s new

Inventory optimization now with customer service level prediction

The IBP for inventory solution process has been enhanced with customer service level prediction.

First, the inventory planner schedules the service level prediction algorithm to calculate the predicted service level. The service level prediction algorithm calculates the time-varying service level at the product-location level, using the time-varying inventory targets as input. The inventory planner then reviews the predicted service level against the average service level to check and learn the impact of the safety stock adjustment.

Planner Workspace for Inventory Planner

New preconfigured Planner Workspaces

Several preconfigured Planner Workspaces are now available for the S&OP process:

- PWS for Consensus Demand Plan

- PWS for Sales Manager

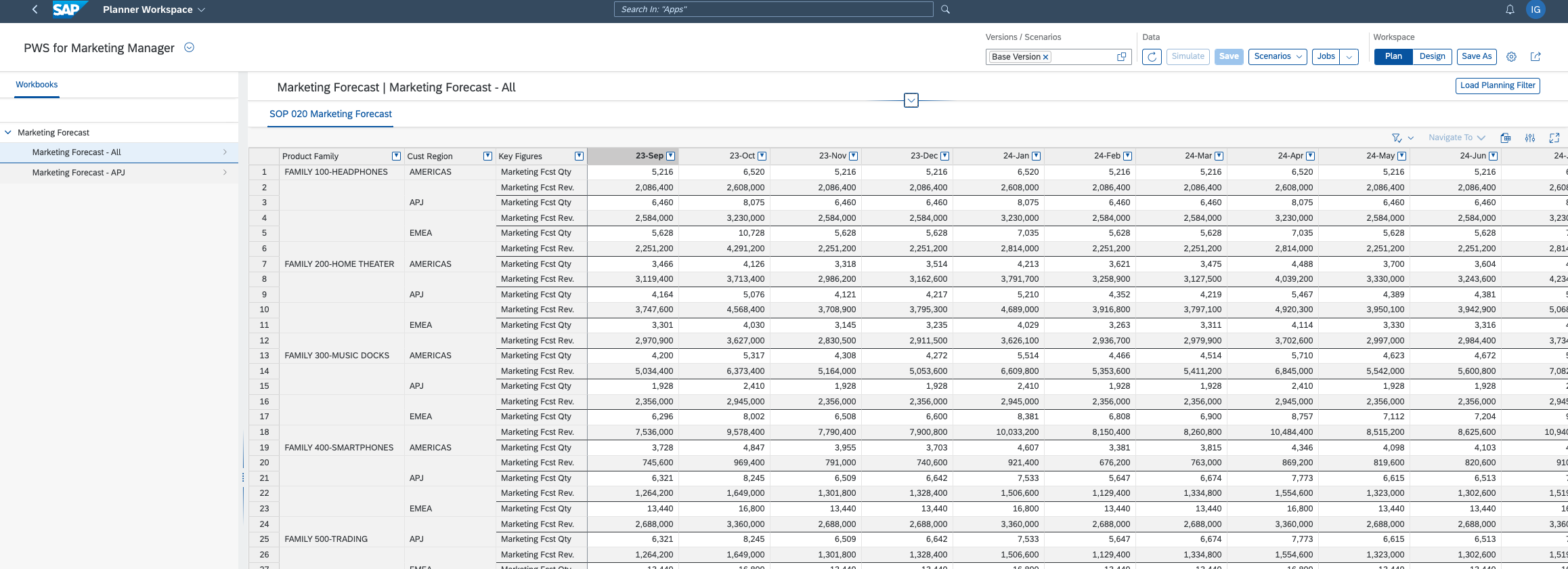

- PWS for Marketing Manager

- PWS for Finance Manager

They are used in the IBP for sales and operations – demand review solution process and allow you to plan, analyze issues in your plans, and solve these issues with the help of customer alerts and simulations.

Planner Workspace for Marketing Manager

Network Aggregation Operator for CO2 emissions rollup

The IBP for sales and operations – footprint analysis solution process has been completely reworked. Now it features a CO2 emissions rollup example using the network aggregation operator (new with 2308) and includes a Planner Workspace with different planning views and charts. This enables the planner to get insights into the carbon emissions of your existing supply plan. The CO2 emissions rollup calculates the CO2 emissions of products at different locations across a planning horizon, considering CO2 emissions incurred at various points in the supply network. Examples are transportation emissions, production emissions, etc. You can then compare different supply plans based on your sustainability KPIs. You’ll see how changes to your supply chain affect the carbon footprint of your products.

Planner Workspace for Footprint Analysis

The ability to evaluate the effect of changes to your supply chain on the carbon footprint of your products and your overall supply plan allows you to make e.g. better sourcing or subcontracting decisions or select the best transit route.

This solution process uses among others the following key figures:

- Local cost at node, for example, CO2 Rollup: Local Carbon Emission at Node (Week/Product/Location): sum of all emissions that are incurred locally at the node in a specific period. This key figure doesn’t aggregate the emissions throughout the supply chain.

Local Cost at Node

- Aggregated Unit Carbon Emission (Week/Product/Location): aggregates the emissions from the supplier to the location including all the emissions caused by procurement, transport, production, and inventory maintenance

Aggregated Unit Carbon Emission

- Shares, for example, CO2 Rollup: Transportation Share of Unit Carbon Emission (Week/Product/Location): aggregates all transport emissions from the supplier to the location. Same for production, external procurement, and so on.

- CO2 Emissions of the overall supply plan (Week/Product/Location): sum of the local emissions at the node + projected inventory*inventory emission rate

Prerequisites:

- Emission rates e.g. for raw materials, production, transportation, and inventory holding need to be integrated from other SAP products (e.g. SAP Sustainability Footprint Management) or external sources

You can also check the release highlight video!

Do you want to access the new content via SAP Signavio Process Navigator? Here you find everything you need.

Do you want to learn more about the usage of SAP Signavio Process Navigator? Please check out this short video.

如有侵权请联系:admin#unsafe.sh