2023-10-12 04:9:1 Author: blogs.sap.com(查看原文) 阅读量:8 收藏

Definition

In subcontracting process, the subcontractor/vendor will be provided with materials (components), which he consumes to produce the finished product.

We have to create MRP area for each subcontractor, If we want to plan provision of components for individual subcontractors separately from the usual requirements.

In this blog we will be discussing about the below mentioned scenarios,

- Stock Transfer of Components to be Provided for subcontracting.

- Third-Party Order Processing for subcontracting.

Stock Transfer of Components

In this case, We will procure the components that are required for subcontracting from a vendor Z and then transfer the stock from the plant storage location to the MRP area of the subcontractor X.

Third-Party Order Processing

In this case, the components to be provided for a subcontractor is procured externally from the vendor Z and then it is delivered directly to the MRP area of the subcontractor X.

Scenario

We will be issuing the component RM material BW-R1003SC and BW-R1004SC to the subcontractor to produce the SFG material BW-S1001SC.

We will perform the Stock Transfer process for the Component RM BW-R1003SC and will perform the Third-Party Order Processing for the component RM BW-R1004SC.

Prerequisite Master Data Setup

- Bill Of material

Using Transaction code CS01 – Create Subcontracting Bill Of material for the SFG Material BW-S1001SC.

- Production version

Using Transaction code MM01 – Assign the Production Version with the Subcontracting BOM to the SFG Material BW-S1001SC

- Material Master – MRP Area and Special Procurement Key assignment

Maintain the special procurement key Subcontracting 30 for the SFG Material BW-S1001SC

For the component material R1003SC. Assign the Subcontracting MRP Area and maintain the Special procurement as Z4 , If Stock Transfer of Components to be Provided to the subcontractor.

In Customizing – Special procurement key Z4 is created for Stock transfer from plant to MRP area.

- Procurement type : F for External procurement

- Special procurement: U for Stock transfer

- Plant: Number of plant 1710 , to which the MRP area belongs.

For the component material R1004SC, Assign the Subcontracting MRP Area and maintain the Special procurement as 20, If the component material is externally procured with delivery directly to the subcontractor .

- Purchasing Info Record

For the SFG Material we should have a valid subcontracting purchasing info record with automatic sourcing indicator.

And for the component RM materials, we should have the standard purchasing info record with automatic sourcing indicator.

Process Flow

- Maintain the Forecast / Demand as Planned Independent requirement.

In Transaction code MD61 maintain the PIR for the SFG material BW-S1001SC at plant level.

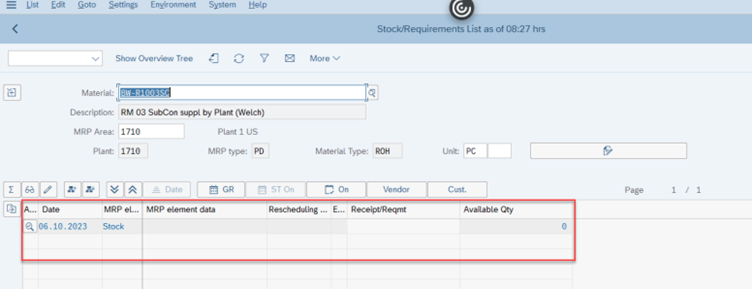

In Transaction code MD04 , Stock Requirement List is displayed.

SFG Material

RM Material

- Material Requirement Planning

In Transaction code MD01N, MRP Live is executed.

In Transaction code MD04, Stock Requirement List is displayed.

For the SFG material BW-S1001SC Subcontracting Purchase Requisition 0010093462 is created.

For the RM material BW-R1003SC

Material Reservation 0000100166 is created for subcontracting (541 Movement type – Goods issue to subcontractor) and a Purchase requisition 0010093464 is created as we don’t have enough stock at Plant MRP Area level.

Transfer requisition 0000100166 (With respect to Material reservation) and subcontractor requirements for the purchase requisition 0010093462 are created at the subcontractor MRP Area level.

For the RM material BW-R1004SC

No MRP element is created at Plant MRP Area level.

Purchase requisition 0010093463 is created as we don’t have enough stock and subcontractor requirements for the purchase requisition 0010093462 are created at the subcontractor MRP Area level.

- Procurement of Component Raw material

For the RM material BW-R1003SC PR 0010093464 is converted to PO 4500491341 and GR at plant / storage location is posted.

For the RM material BW-R1004SC PR 0010093463 is converted to PO 4500491342 and GR at subcontracting vendor location is posted.

- Processing of Subcontracting Order

For the SFG material BW-S1001SC , The Subcontracting Purchase Requisition 0010093462 is converted to Subcontracting Purchase order 4500491343 using the transaction code ME21N.

In Transaction code ME2O, the component material are issued to the subcontractor.

For the component RM material BW-R1003SC, the subcontracting stock is Zero.

For the component RM material BW-R1004SC ,We have already received the stock directly in supplier location. So the subcontracting stock is 100.

For the component RM material BW-R1003SC, the required quantity is posted to the subcontracting vendor location after stock transfer.

Both the component RM materials BW-R1003SC and BW-R1004SC has the required stock in the Subcontractor Location.

In the transaction code MIGO, Perform Goods receipt against the subcontracting purchase order is performed.

In the transaction code MD04 – Stock Requirement List, the forecasted quantity is procured by subcontracting process.

Conclusion

By planning the components that are required in Subcontracting Process, We can transfer the plant stock to the subcontractor Location or we can make the Vendor to deliver it directly to the subcontractor Location.

When the subcontractor delivers the finished material, the goods receipt is posted to the subcontract order. The stock with subcontractor and the reservations are then reduced.

Additional reference

如有侵权请联系:admin#unsafe.sh